See This Report about A1 Professional Asphalt & Sealing Llc

Table of ContentsThe smart Trick of A1 Professional Asphalt & Sealing Llc That Nobody is Talking AboutNot known Factual Statements About A1 Professional Asphalt & Sealing Llc How A1 Professional Asphalt & Sealing Llc can Save You Time, Stress, and Money.Get This Report on A1 Professional Asphalt & Sealing LlcA1 Professional Asphalt & Sealing Llc Fundamentals Explained

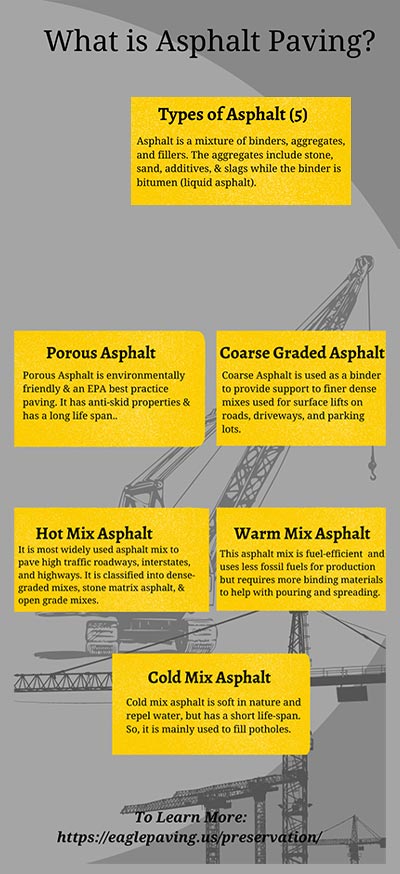

In its make-up, asphalt is composed largely of Asphalt integrated with numerous kinds of accumulation, such as sand or crushed rock. Pavement, alternatively, is a kind of concrete which contains aggregates, cement, and water. asphalt paving repairs. Depending on the area and usage of the used pavement product, a blend of different chemical admixtures may be contributed to make it a lot more durable

What is the distinction in between asphalt and blacktop driveways? Sidewalk can be made of either asphalt or concrete, with asphalt being smoother and much more durable due to its binder, while concrete hardens with the curing procedure yet tends to put on down over time due to weathering.

A1 Professional Asphalt & Sealing Llc for Dummies

It is additionally much more lightweight and cost-efficient. Just how do I maintain my asphalt driveway? The most vital part of maintaining an asphalt driveway is ensuring it's correctly secured. This shields the surface area of your driveway from rough weather, salt, and other destructive materials. https://sitereport.netcraft.com/?url=https://a1asphaltpro.com. You need to reseal the surface area every 2 or 3 years for optimum defense.

Asphalt and sidewalk are typical components on roads all over. In spite of their resemblances, these two materials have some vital distinctions that make each ideal for various situations.

Understanding these differences can assist ensure an ideal choice is made when selecting a surface option. You can check out extra short articles like this one here.

The Greatest Guide To A1 Professional Asphalt & Sealing Llc

Recently, State highway firms and FHWA were impressed by an exploration: The clandestine use of re-refined engine oil bases in asphalt is extensive. Simon Hesp, Queens University (Kingston, Ontario) Asphalt is the sticky black deposit that is left over from the handling of petroleum. It has actually been used in paving for more than a hundred years.

The asphalt, which functions as the sidewalk's binder, is also the most costly component of the cost of the product for leading roads. The weight of an asphalt pavement varies relying on the accumulation type, the asphalt, and the air gap content. Making use of an ordinary instance of 112 extra pounds per square yard per inch of density, a 1-mile (1.6-kilometer)-long, four-lane highway with a 4-inch (10-centimeter) lift and 12-foot (3.6-meter)-wide lanes evaluates concerning 6,300 loads (5,700 metric loads).

The 300 heaps of asphalt in 2002 would certainly have cost around $48,000. By 2006 this would certainly have increased to $96,000 and by 2012 to $183,000. That is a boost of regarding $135,000 for every mile of highway in just 10 years. The rising rate of asphalt had a major influence on the cost of building pavements, which boosted rate of interest in discovering ways to lower expenses.

5 Simple Techniques For A1 Professional Asphalt & Sealing Llc

RAP currently contains asphalt, albeit aged product that does not have the very same residential properties of fresh asphalt. During a hallway conversation at a 2010 technological conference, Matt Mueller, then a State designer of products from Illinois, disclosed that his division of transport had actually found phosphorous in one of the asphalt binders it was acquiring.

The vendor denied adding PPA, yet declined to disclose what had been included in the binder. When pressed by the division of transportation, the vendor exposed that it was adding what it called an asphalt extendernow recognized to be re-refined engine oil bases (REOB). REOB has a percentage of phosphorus, which is what division chemists originally determined.

"Nobody understood this product was being included in asphalt, had seen any type of study on exactly how this might affect performance of hot-mix asphalt sidewalks, or recognized for for how long and how extensively it was being used throughout the country," says Mueller. After discussions at the technical conference, he says, "It swiftly went from being use this link simply a problem in Illinois to ending up being a nationwide and global worry." Component of the goal of the Chemistry Research Laboratory at TFHRC is to develop new test techniques.

The residential or commercial properties of asphalt binders differ extensively depending on the source of the unrefined oil and the refining procedure made use of. For low winter months temperature levels, softer asphalts are required to prevent splitting.

A1 Professional Asphalt & Sealing Llc for Dummies

A machine called a dynamic shear rheometer (DSR) was introduced to the sector during the Strategic Freeway Research Program's study project, which ran from 1987 to 1992. The DSR is currently the sector standard for measuring the viscoelastic buildings of paving asphalt. The device was not created for the paving industry (https://www.storeboard.com/a1professionalasphaltandsealingllc).

The DSR makes it possible for product designers to develop toothpaste with the appropriate uniformity so that it can be pressed from a tube however not drop off the toothbrush. The DSR examinations binder put in between two parallel plates about the size of a quarter. One of home plates moves and the device measures the viscoelastic properties of the asphalt.